Specifications

1.Temper

| Type | Hardness | Hardness Aim (HR30T) | Applications |

| Single Reduce |

T1 | 49±4 | Deep-draw cans, cans, etc. that require high flexibility. |

| T1.5 | 51±4 | Deep-draw cans, cans, etc. that require high flexibility. | |

| T2 | 53±4 | The deep draw of the general degree. | |

| T2.5 | 55±4 | General purpose. Both T2 drawability and T3 toughness. | |

| T3 | 57±4 | General purpose. Has a certain degree of toughness. | |

| T3.5 | 59±4 | It has strong toughness and is used for cans or ends that require materials of between T3 and T4. | |

| T4 | 61±4 | It has strong toughness and is used for can body, ends and crown cover. | |

| T5 | 65±4 | For applications requiring excellent buckling resistance, can body and ends. | |

| Double Reduce | DR7M | 71±5 | High-strength food cans, beverage cans and other high-intensity applications. |

| DR8 | 73±5 | High-strength food cans, beverage cans and other high-intensity applications. | |

| DR8M | 73±5 | High-strength food cans, beverage can bodies, Twist off caps and other high-intensity applications. | |

| DR9 | 76±5 | Twist off caps and other high strength applications. | |

| DR9M | 77±5 | Twist off caps and other high strength applications. | |

| DR10 | 80±5 | High-strength applications such as pressing open the cover. |

Note: Tinplate is used in a wide range of applications. The above table is for reference only.

2.the annealing method

(1) Annealing methods include continuous annealing and box annealing.

When continuous annealing is specified, the code name "CA" is added after the tempering specification code, such as T4CA;

When box annealing is specified, the code name "BA" will be added after the specification code specification, such as T1BA.

(2) Soft materials (T1, T2, T2.5, T3 can now provide ultra-low carbon continuous annealing steel (IF steel), the material has excellent comprehensive performance, almost completely replace the original BA material.

For details,please consult us.

3.Tin Coation Weight

| Type | Nominal coating weight (g/㎡) | Minimum average coating weight (g/㎡) | Code of coating weight |

| Equal Coating | 1.1/ 1.1 | 0.90/0.90 | 10/10 |

| 2.8/2.8 | 2.45/2.45 | 25/25 | |

| 5.6/5.6 | 5.05/5.05 | 50/50 | |

| 8.4/8.4 | 7.55/7.55 | 75/75 | |

| 11.2/11.2 | 10.1/10.1 | 100/100 | |

| Poor tin plating | 1.1/2.8 | 0.90/2.45 | 10/25 |

| 2.8/5.6 | 2.45/5.05 | 25/50 | |

| 2.8/8.4 | 2.45/7.55 | 25/75 | |

| 2.8/11.2 | 2.45/10.1 | 25/100 | |

| 5.6/8.4 | 5.05/7.55 | 50/75 | |

| 5.6/11.2 | 5.05/10.1 | 50/100 | |

| 8.4/11.2 | 7.55/10.1 | 75/100 |

Note:

(1) The coating weight is determined according to the end use of the product. Tinplate with heavy coating is used for cans with high corrosion resistance or cans without printing. Tinplate with light coating is used for cans with low corrosion resistance requirements or cans with printing.

(2) Differential Marking for the tinplate, in order to clarify the difference in coating weight, a white thin marking line is drawn on the edge of the strip, which we call “D-Mark”. In general, if the customer does not have special requirements, the marking line must be attached to the side of the light tin coated surface.

Such as:11.2/2.8D 2.8/1.1D

(3) Other forms of differential markings At the request of the customer, some are marking the pattern of a particular pattern on the entire surface. This type of marking is called "A-mark". Its marking line can be attached to heavy tin coated surface or light tin coated surface.

Such as: 11.2A/5.6 2.8A/11.2 Differential coated products must use the marking (“D” or “A”), the request for cancellation of the mark is not acceptable.

4.Surface Finish

| Surface Finish | Sign | Aiming Ra (μm) | Features and Applications |

| Bright Extra | BE | 0.10-0.20 | The brightest surface. |

| Bright | B | 0.20-0.35 | Bright surface. generally used. |

| Stone | R1 | 0.35-0.50 | Stone surface. The defects caused by printing and can making are not conspicuous. |

| Super Stone | R2 | 0.50-0.70 | Rough stone surface. |

| Matte | M | 0.70-1.20 | Dull finsh. For crown or DI cans (the tinplate is not reflowed). |

| Silver | S1 | 0.70-1.20 | Dull finish,for DI can or art can. |

| Satin | SA | 1.80-3.00 | Rougher than dull finish,for art can. |

5.Steel Type

| TMBP only lists representative steel type | ||

| Steel type | MR | It has few residual elements and has excellent corrosion resistance, and is widely used in general applications. |

| L | Cu, Ni, Cr, Mo and other residual elements are extremely rare, and are used as excellent corrosion-resistant cans. | |

| D | Used for deep drawing or non-aging applications. | |

6.Chemical treatment (passivation)

| Chemical treatment | Process | Applications |

| #311 Processing | Cathodic electrochemical passivation treatment of sodium dichromate | Mainly used for printing purposes, the most widely used. |

| #300 Processing | Sodium dichromate impregnation passivation treatment | A representative example is tinplate for DI cans, although it is also used in other foods can without printing (eg, mushrooms, etc.) but rarely. |

| #71 Processing | Chromic acid cathode electrochemical passivation treatment | It has excellent coating adhesion and is mainly used for printing applications. |

7.Oil type and Oil weight

| Oil type | Oil weight |

| DOS (DI-Octyl-Sebacate) | According to the application, the target center value can be 2 mg/㎡, 3 mg/㎡, 6 mg/㎡, or it can be increased or decreased according to the actual situation of the user. |

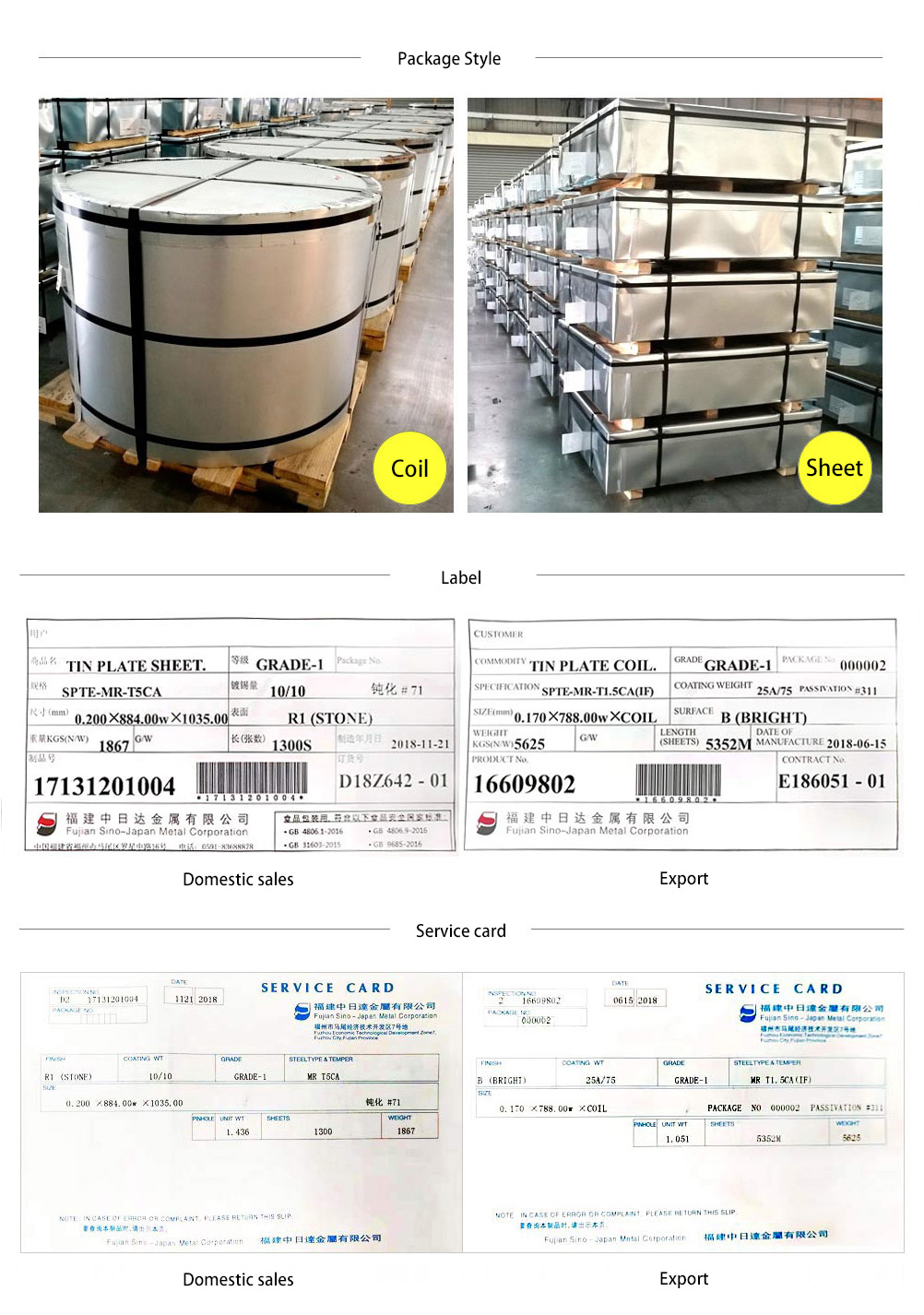

8.Packaging form, Label and Service card