CRAFTS

|

2

|

1

Wide plate

The largest wide board that can be produced up to 1100mm |

|

2

Automatic centering welding machine

Introduced a Japanese company to manufacture a welding machine that can be automatically aligned. |

3

High precision tension control system

The 6 sets of tension roller and 5 sets of tension meter implement closed-loop control, which can realize precise control of soft and thin materials and stable production at high speed. |

|

4

Tension leveler

It meets the requirements of high surface flatness (high-speed multi-color, high-precision, fine-grained printing). |

5

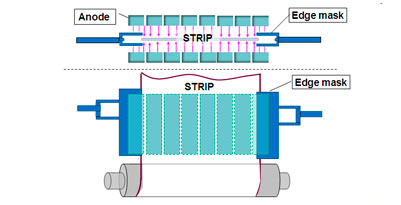

Steel strip edge cover

The newly developed steel belt edge cover prevents thick tin edges and ensures uniform tin plating on the surface of the steel strip. |

|

6

Soft melt equipment

The introduction of high-performance, high-durability reflow equipment manufactured by Japanese companies ensures stable production of tinplate with high corrosion resistance and uniform surface tin. |

7

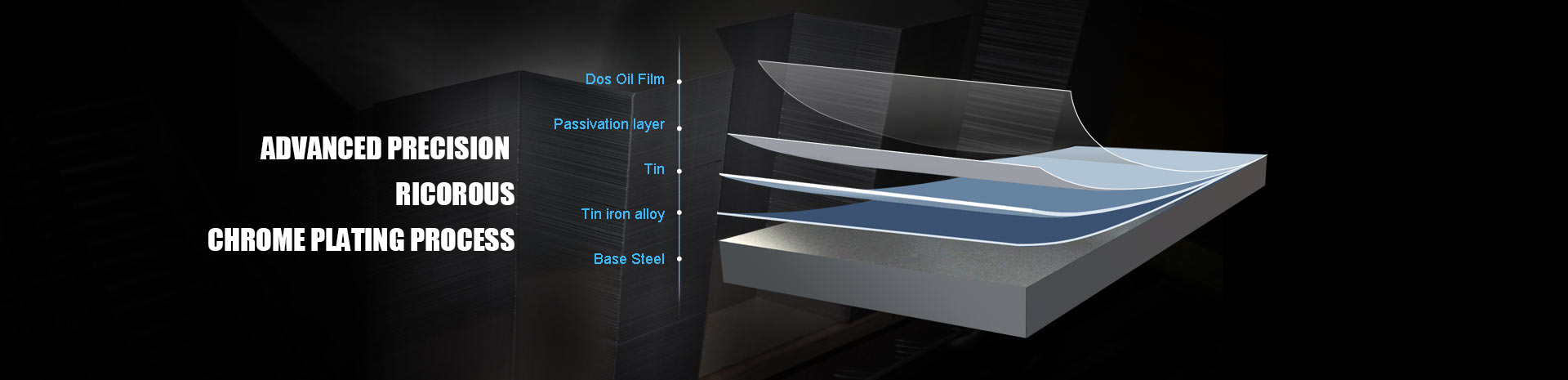

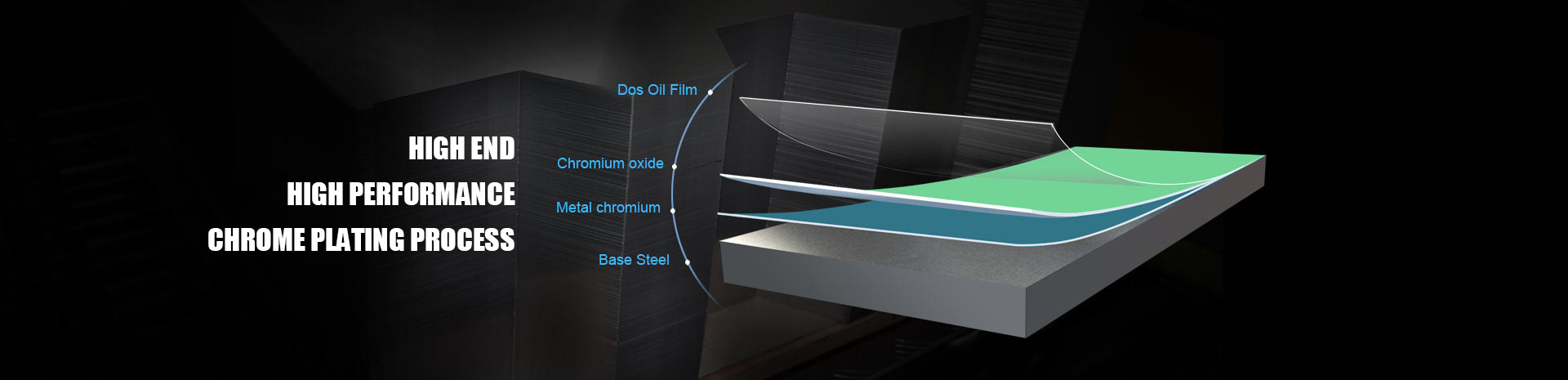

Added #71 specification passivation

Passivation treatment specifications In addition to #311, #300, #71 passivation treatment technology meets the application of high paint adhesion. |

|

8

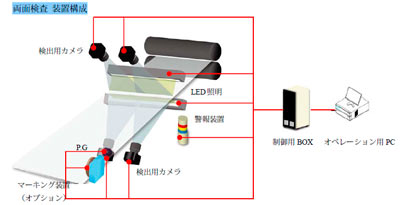

Online CCD surface defect automatic inspection system

The CCD surface defect meter manufactured by a Japanese company was introduced, and the full-length inspection in the width direction was carried out to strengthen the quality management system. |

9

Online Thickness Tester (γ-ray)

A plate thickness measuring instrument (γ-ray) manufactured by a German company was introduced, and the thickness of the plate was continuously measured online. |

|

10

Online tin plating measuring instrument(X-ray)

The introduction of a tin-plated measuring instrument (X-ray) manufactured by a German company can continuously measure the amount of tin plating in the whole plate width direction on the line, and find that the tin plating amount is out of range and can be marked with a biased mark in time. |

11

Online pinhole instrument

The introduction of the pinhole instrument manufactured by the German company can continuously detect the pinhole of the whole plate width on the line. Once the pinhole is found, it can be marked in time. |