Tinplate

Tin-plated steel sheet (tinplate) refers to a cold-rolled low-carbon steel sheet or steel strip coated with commercial pure tin on both sides. Tin mainly acts to prevent corrosion and rust. It combines the strength and formability of steel with the corrosion resistance, solderability and aesthetic appearance of tin in a material that is corrosion-resistant, non-toxic, suitable strength and processability. In addition to metal packaging, The main materials are used in the food packaging, and are also widely used in various industries such as electronic components and batteries.

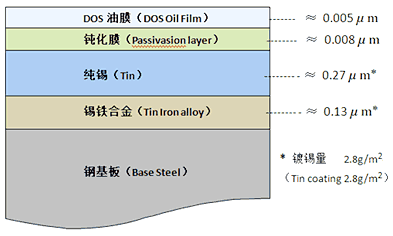

Cross section of tinplate:

镀锡钢板 (Tinplate)

Tin Free Steel

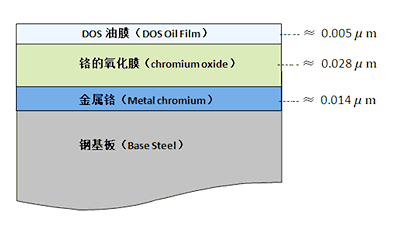

A chrome-plated steel sheet is a cold-rolled steel sheet that does not use tin as a coating. The substrate is the same as tinplate, but the coating is surface treated by electrolytic chromic acid treatment. The upper layer of the coating is hydrated oxide of chromium and the lower layer is metallic chromium. The chrome-plated iron is widely used for ends of metal containers, coated iron, etc. because the coating adhesion of the group and the heat resistance of the coating.

Cross section of chrome-plated iron:

镀铬钢板 (Tin Free Steel)

The existing containers include iron cans, aluminum cans, papers, and plastic containers, and the recycling characteristics of these containers are different, but the iron cans are superior in recycling treatment to other packaging materials. Based on the increasingly strict international environmental management, tinplate cans with low pollution, recyclability and resource-saving characteristics will have a broader development space in future packaging applications:

Low pollution

The main raw material tinplate in the iron can container is in fact environmentally friendly and can be naturally decomposed, because when the iron can exists in the environment, it can naturally oxidize and return to the original iron oxide state, returning to nature, so the scrap iron can The stacking can be decomposed by time and will not cause environmental pollution. At the same time, it is not necessary to cut down trees to make iron cans, and it will not destroy the ecological balance.

Recyclable

The iron can itself has a characteristic that is not found in other packaging materials - it can be adsorbed by the magnet, so that the magnetic can be used to separate the iron can from the waste by the magnetic force, and the garbage can be easily recovered by using this feature. The effect of 80% iron cans. The invention of environmental protection cover not only makes the use of iron cans safer and healthier, but also effectively reduces the amount of garbage, and has direct and obvious benefits for recycling operations.

Provincial resources

In the removal of other polluting residues on the iron can, the chopper equipment has been developed to effectively remove more than 98% of the pollutants and provide good quality iron scrap. In addition, the United States also pointed out that the presence of aluminum easy-opening is conducive to scrap iron re-production because it can reduce the amount of Hot Metal used in steelmaking and reduce the cost of overall steel manufacturing. In addition, in terms of energy conservation, the report pointed out that the use of tinplate waste to produce steel can save 230m3 of natural gas per ton of scrap iron scrap compared to iron ore production, so the recycling process of tin can reduce the global environment. With the impact of energy, it is in line with future product trends.