EQUIPMENT

∠ Ferrostan Continuous plating Video

|

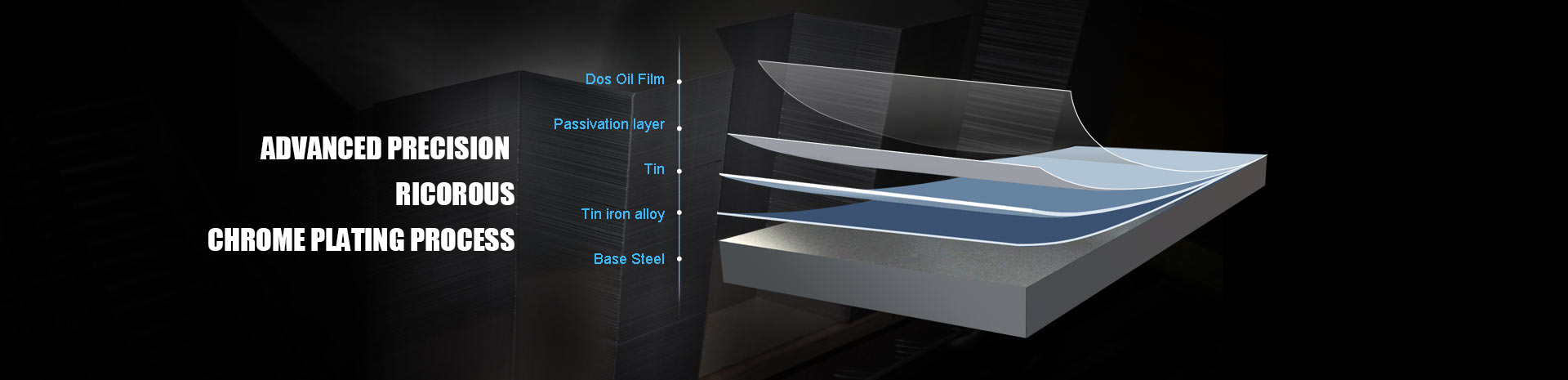

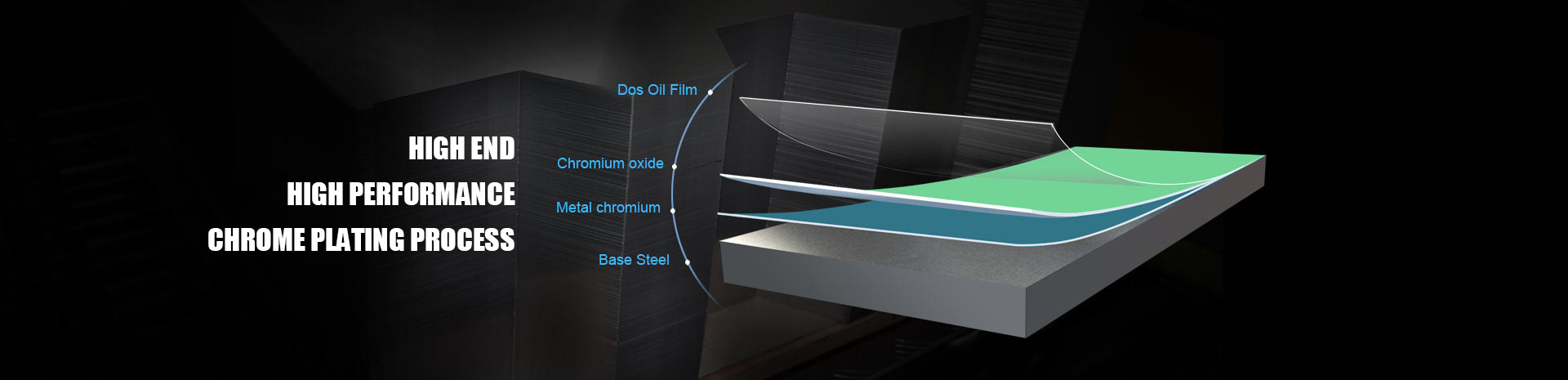

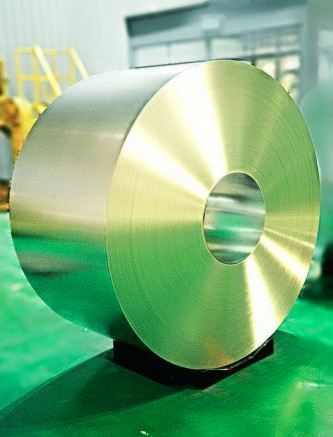

Leading technology is the guarantee of product quality. FSJMC has advanced tin plating production equipment and the production process is fully automated. At present, there are two continuous automatic tinning production lines, Ferronstan type, the production line is equipped with CCD automatic surface inspection system, which can realize the intelligent inspection of surface defects; the self-developed fusible tin plate edge protection device has obtained national patent. Effectively solve the problem of thick tin and other issues, and further improve the product quality. After the second tin plating production line was put into production in 2017, the product specifications were more substantial, and the thickness of the plate can be as thin as 0.12-0.60mm, the width of the plate can be up to 1100 mm, and the tin plating amount is from 1.1 g/m2 to 22.2 g/m2, with 300, 311, 71 passivation process, flat shears and wave shears produced by high-precision shear line, can fully meet the various needs of the market. Products are widely used in dozens of high-end industries such as food, beverages, milk powder, batteries, electronic components. In 2019, the company launched a new variety of chrome-plated iron to provide customers with more high-end packaging materials.

|

|

Online CCD surface defect automatic inspection system |

High precision tension control system |

Passed ISO9001 and FSSC22000 certification |

|

Wave shear |

Flat shear variety |

Coil variety |